- How to improve the life wire EDM flushing nozzles

- The article citations: Editor:xiaoyunone Sentiment:1466 Published time:2014-03-16

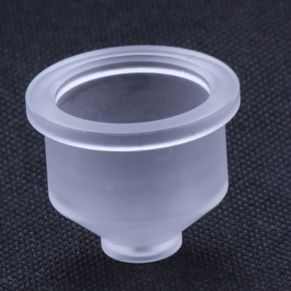

Factors affecting the life of CNC wire EDM flushing nozzles are more, Kenos tell you how to improve the life wire EDM flushing nozzles? The main aspect relates to equipment, personnel, materials, and take the following measures to increase the life of wire EDM flushing nozzles the value to some extent.

1.Wire EDM flushing nozzles installed between the span to be adjusted to improve its

stability, avoid vibration; replacement fluid, the working fluid is difficult to obtain

the required time high life, because the work was gradually increased in the metal

particles and the large gradient that changes the nature of the working fluid, the

working fluid reducing effect, but also clogging wire EDM flushing nozzles, the fluid

must be filtered using a long time to replace the fluid.

2.According processing experience, the effect of the new configuration of the working

fluid is not the best, in use around 20H, the surface roughness value of the minimum of

its processing. Also, to improve the service life of wire EDM flushing nozzles, the

working fluid can be formulated slightly more dilute working solution can not be mixed

with other impurities in the liquid, so as not to affect the service life of wire EDM

flushing nozzles.

3. Wear check wire EDM flushing nozzles need cleaning when dirty washing liquid.

How to improve the life of wire EDM flushing nozzles is WEDM operator must know

knowledge! Long life wire cut water nozzles for the company to save costs and

increase productivity to achieve higher profit margins!

- ◎ Won the title of "best electronic r...

- ◎ Guangdong lions partition 8 eight n...

- ◎ Organize employee travel

- ◎ Dongguan net chamber of commerce to...

- ◎ Guangdong lions certificate

- ◎ The lion love star award

- ◎ The lion in love without a certific...

- ◎ KENOS have good quality products an...

- ◎ I grow rich because of acting as an...

- ◎ It is my right choice to join in KE...

- 1The material of ...

- 2Sodick diamond w...

- 3Why EDM power fe...

- 4Wire EDM Fundame...

- 5How to ensure th...

- 6what's the Low s...

- 7KENOS analyzes l...

- 8How to correctly...

- 9Cutting piece of...

- 10What is power fe...